WISDOM AUTOMATION.CO.LTD

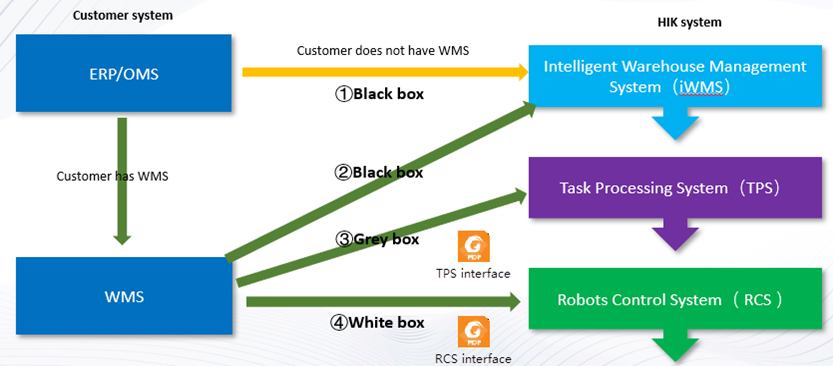

is System integratorand Artificial Intelligence AI who offers Engineering Design as well as

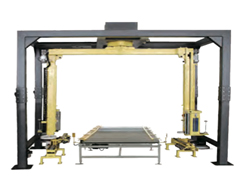

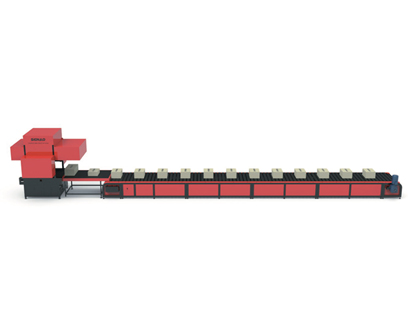

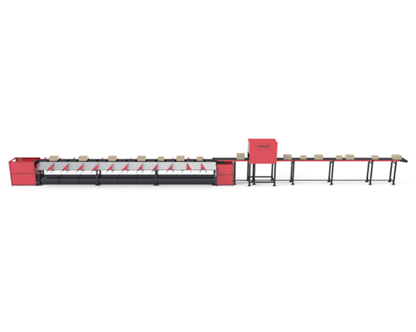

Full Range Service associated with forward thinking DC (Distribution Center) and Warehouse by applying ASRS (Auto Storage and

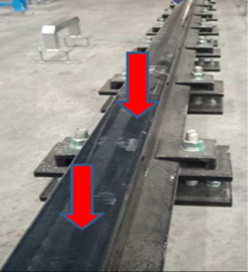

Retrieval System) and Automated Guided Vehicle( AGV) and Automated Item Pick (AIP) plus Digital Embedded Technologies and

Smart Devices to enhance clients’ efficiency.